| CUSTOM SOLUTIONS |

|

|

1 |

Material |

Zinc alloy, or iron and brass for optional...etc |

| 2 |

Color |

Customize your favorite color |

| 3 |

Logo |

Customize with your own design |

| 4 |

Package |

Poly bag/Bubble bag/OPP bag/ Plastic box/Gift box |

| 5 |

Sample cost |

Depend on sample type or artwork and size |

| 6 |

Delivery time |

7-15 working days |

| 7 |

Shipment |

Seafreight,Airfreight,DHL,UPS.FedEX, or use your own forwarder |

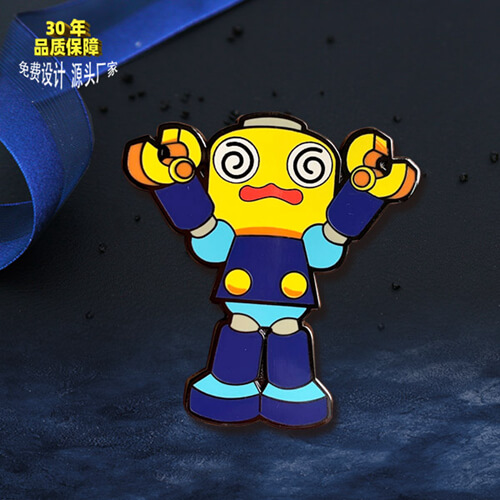

Features of Baked Enamel Enblem

Painted badges are a type of badge. The general materials used are copper, iron, zinc alloy, etc. Among them, copper is the most commonly used and relatively expensive. Iron painted badges are the cheapest. Their surfaces have obvious concave and convex feeling and good texture. They are suitable for the production of some mid-to-high-end badges.

Company Profile

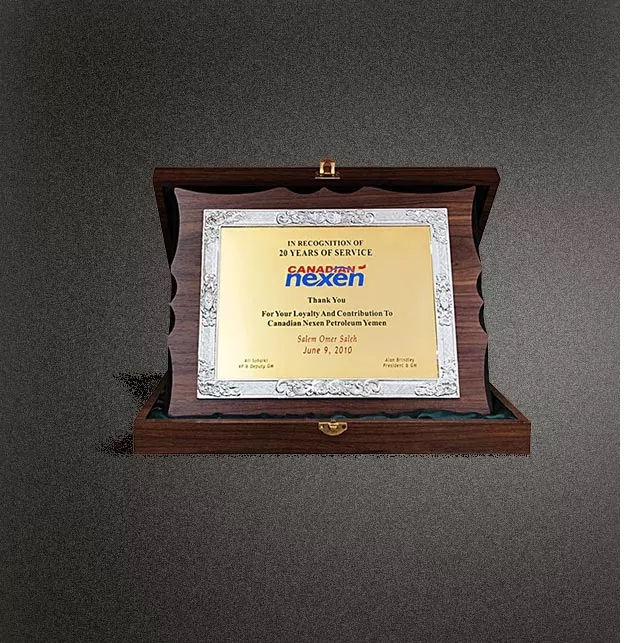

Ever since 1991, we have been doing customized stuffs including emblem, medal, badge, commemorative plate, etc. using different material like metal, wood, glass, crystal, acrylic, ceramic, fabric, leather.

Means of production involves stamping, etching, laser cutting, woodworking, 3D sculpture, sublimation, embroidery, UV printing, and cast of metal by lost wax process or by mold for resin…etc.

FAQ

Q1. Are you a manufacturer or trade company?

- We are manufacturer of metal crafts. Welcome to our factory and have a field visit.

Q2. How long is your delivery time?

- Generally, it is 5-10 days if the goods are in stock, or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q3. Is the quality of your product guaranteed?

- Our QC will control the quality one by one before the delivery. So you do not need to worry about that. We have more than 10 years of production experience.

Q4.1'm looking for some products which are not shown on your website, can you make me a special order?

- We value our cooperation between us. So, you can show us a picture of the produce you need, or we design it for you according to your idea.

Q5. UPS /TNT / DHL Express lost/broke my package, how could I do it?

- If you didn't receive it in time, please let us know, and we'll check with Express and get you an answer.

- If you just received part of your products, some cartons lost or broken, please complain to the shipper and take a photo when you touch them, Let us know the first time, and send us the photos, and we'll re-make the lost items for you for free and make a claim on this to express.

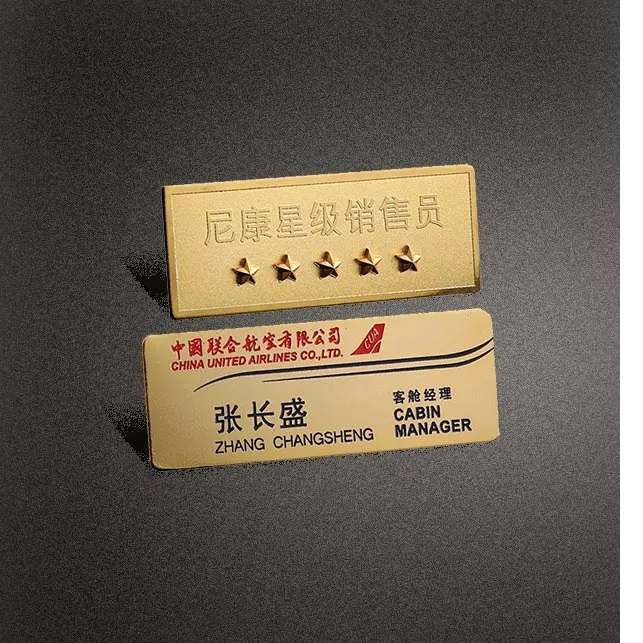

A specially formulated chemical acid is used to corrode and make the words and patterns appear. It is often used in employee badges, metal badges, work badges, nameplates, and plaques.

The badges are stamped, die-casted, and injection-molded in one go using a stereotyped mold developed and manufactured by skilled craftsmen. They are mostly used in the production of metal badges, logos, and high-end badges. They are often known for their three-dimensional effect.

1. Surface Coating: The surface of the paint badge can be coated with transparent protective resin, and dripping glue results in a bright and smooth surface. This kind of paint badge is also known as a drip-molded badge.

2. Appearance and Price: It has bright colors, clear lines, and a strong metallic texture. The price is relatively lower than that of the imitation enamel badge and the enamel badge, making it a top choice for mid - to - high-end badge production.

3. Application: Copper paint badges are widely used in company badges, mid - to - high-end team badges, and some collection badges.

ACCESSORIES:

| Parameter |

Description |

| Material |

Usually made of copper or other suitable metal bases. |

| Production Process |

Involves baking enamel on the metal surface at high temperatures. |

| Color |

Rich and vivid colors with good colorfastness, able to maintain long - term luster. |

| Appearance |

Smooth enamel surface with clear and beautiful patterns, presenting an elegant and high - quality look. |

| Durability |

High durability, resistant to wear, corrosion, and fading over time. |

| Thickness of Enamel Layer |

Varies, but typically provides a substantial and stable coating. |

| Cost |

Moderate to high, depending on the complexity of the design and quality requirements. |

| Application |

Commonly used for high - end badges, commemorative badges, medals, and awards. |

Contact information:

For more information about our products please contact us.

Email:https://www.pymedal.com

Mobile: +1 6692529286(WhatsApp, Wechat)

Address: Xiayuan Village, Ningxia Street, Zengcheng District, Guangzhou City, Guangdong Province20 Sai Ma Nam Roadneeds.

CN

CN

HOME

HOME

Related Suggestion

Related Suggestion

Mar 26,2025

Mar 26,2025

Tel

Tel

Email

Email

Address

Address